When faced with a crisis that impacts fuel supply lines, it can be tempting to panic and take unnecessary emergency measures that end up costing your drivers time and fuel. With rising fuel prices and more looming fuel shortages, now is the time to make sure your system for inventory forecasting is as accurate as possible. This way, you’ll be able to keep a calm head and weather whatever comes while also being able to accurately and efficiently keep your fleet fueled and on the road.

Improving Your Forecast

The first step to improving your inventory forecast is to make sure your current forecasting strategy is answering the two most important questions:

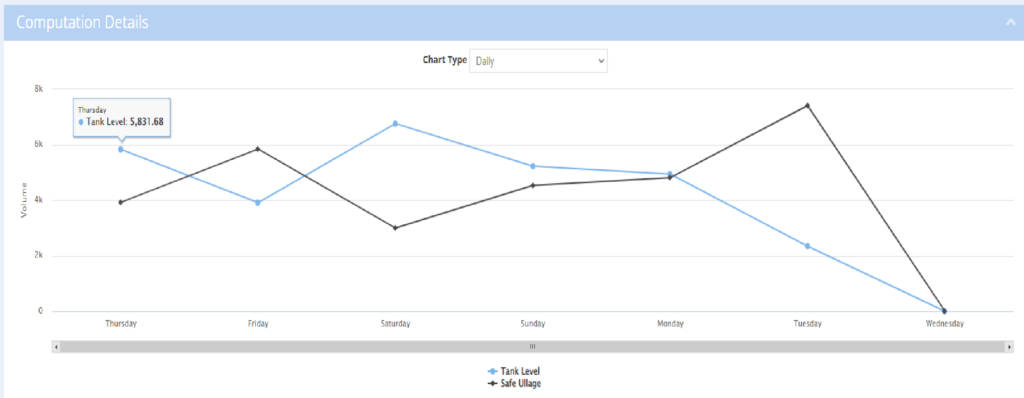

When will a load of fuel fit into the tank?

Knowing the answer to this question will help you avoid nasty fuel spills where the clean-up will cause delays. It’s important to know when, with as much accuracy as possible, a tank will be low enough that it can be filled without spilling.

When will the tank run out of fuel?

Some fuel tanks are small and only hold a few days’ worth of fuel while others are much bigger, holding weeks’ worth of fuel at a time. It’s important to know the exact amount each of your fuel tanks hold so that you can determine when it will run dry. You want to avoid a tank completely running out of fuel because that can also cause delays as drivers are stuck waiting for it to be filled.

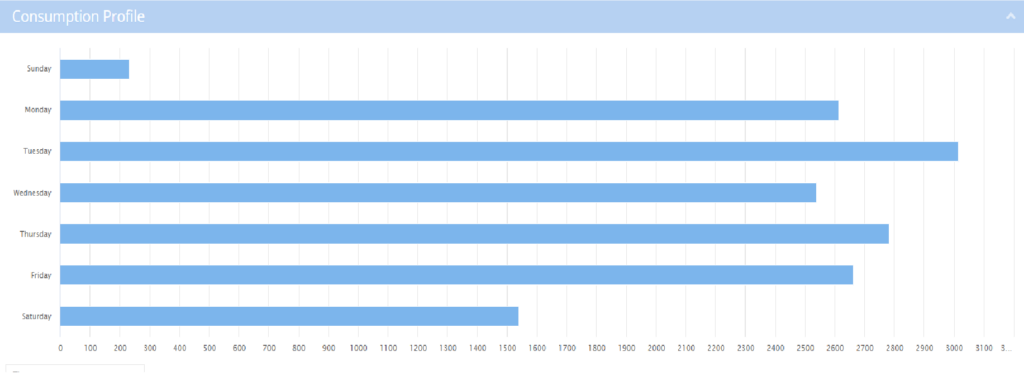

Another element to consider when you are forecasting your inventory levels and scheduling is the fueling habits of your drivers. Are they early morning fuelers, making sure their tank is topped off before leaving for the day? Are they evening fuelers, making sure their rig is fueled and ready first thing in the morning? Knowing when your drivers are fueling is a key part to understanding when your tanks will be at their lowest.

Once you have collected all of the relevant information, it’s time to schedule the deliveries. You want to be able to schedule refuels somewhere in the sweet spot between when the tank has enough space for a load of fuel and when the tank will run dry, with some wiggle room because, like all deliveries, there’s no way to schedule a fuel delivery for the same time, all the time.

Let’s say, for example, you know that at one of your tanks, it will be able to fit a load of fuel at 10 AM on Wednesdays and will run dry by 10 PM that same night. The ideal delivery window would be between 2 PM and 6 PM.

How this helps during fuel shortages?

An accurate inventory forecast is the first thing you need to be able to set up a long-term delivery schedule. If you can work with a supplier and say with a high degree of confidence that you will always need a load delivered between 2 PM and 6 PM every Wednesday, you will be able to build a relationship with that supplier that can withstand temporary shortages.

Suppliers want customers they can reliably sell fuel to. They want customers that have a solid grasp of their inventory and know, in advance, when they will need fuel deliveries. These are the customers that fuel suppliers will sell to first when there is a limited supply.

Diversified has a long history of helping fleet managers like you dial in the most accurate inventory forecasts for their fleet. Let us help you ensure your forecast is one that will see you through good times and bad